Advantages and disadvantages of micro electroforming

Micro electroforming is a machining process based on the principle of electrochemical cathodic deposition. It involves continuously reducing and depositing metal cations onto a cathode mold to form an electroformed […]

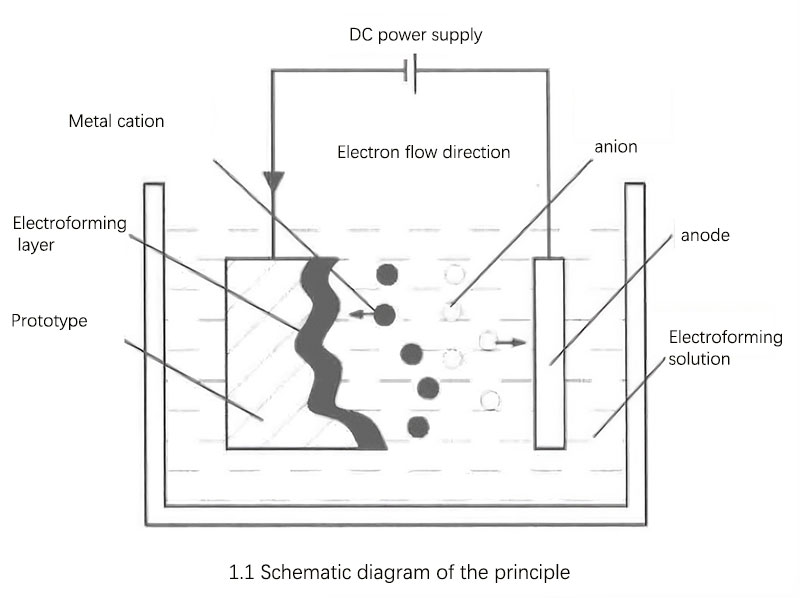

Micro electroforming is a machining process based on the principle of electrochemical cathodic deposition. It involves continuously reducing and depositing metal cations onto a cathode mold to form an electroformed part, as shown in Figure 1.1. In this process, the electroformed metal material serves as the anode, the conductive mold acts as the cathode, and a salt solution of the electroformed metal material is used as the electrolyte. The anode metal loses electrons and generates metal ions, which then continuously deposit on the cathode. When the deposited metal layer reaches the desired thickness, the power supply is disconnected, and the deposited layer is separated from the mold, resulting in an electroformed part with a shape opposite to that of the mold.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Micro electroforming has the following advantages.

- Accurate and precise replication of complex contours and fine details, with high replication accuracy and repeatability.

- The obtained electroformed parts have very high dimensional accuracy, with a surface roughness of up to Ra 0.1μm, and consistency among electroformed parts produced from the same mold.

- Wide applicability, as the size of the electroformed parts can vary within a large range. It can convert difficult-to-machine precision internal contours into easily machinable external contours, making it suitable for the manufacturing of precision and complex internal contour parts.

- Within a certain range, the mechanical and physical properties of the deposited metal can be adjusted by changing the electroforming conditions and electrolyte formulation. It can also join materials that are difficult to weld using the electroforming method.

- The equipment investment is relatively small, and the cost is low. The machining allowance is small, and the waste material can be reused as anode material. The molds and electroforming solutions can also be reused.

However, micro electroforming also has some limitations and drawbacks.

- Low electroforming speed, resulting in long processing times. For example, to obtain a 1mm thick deposited layer, simple-shaped parts may require several hours, while complex parts may require tens of hours.

- The quality of the deposited layer is unstable and prone to defects such as nodules, pinholes, coarse grains, and excessive stress, leading to a decline in the physical and mechanical properties of the deposited layer and potential part rejection. Excessive internal stress can also cause deformation and cracking of the deposited layer.

- The metal deposition rate is generally proportional to the current density on the cathode surface. For complex mold surfaces, the uneven distribution of the electric field can result in poor uniformity of the deposited layer, affecting the part’s performance. Moreover, this non-uniformity tends to worsen with longer deposition times, creating a vicious cycle and significantly reducing the average deposition current density and deposition rate.

- The limited range of electroforming materials may not meet all practical needs.

Micro electroforming technology serves as a crucial support for microfabrication techniques such as LIGA, LIGA-Like, and EFAB. It finds extensive applications in aerospace, precision machinery, automotive electronics, biomedical, and defense industries. Examples include micro molds for biosensors, micro turbines, high aspect ratio micro holes, and microflow meters.