How to dress a carbide grinding wheel?

I. Overview of dressing techniques for Superabrasive grinding wheels Superabrasive grinding wheels, due to their extremely high hardness, are difficult to dress using traditional methods. Therefore, various specialized dressing techniques […]

I. Overview of dressing techniques for Superabrasive grinding wheels

Superabrasive grinding wheels, due to their extremely high hardness, are difficult to dress using traditional methods. Therefore, various specialized dressing techniques have been developed. These techniques include diamond pen dressing, roller dressing, and grinding wheel dressing, each with its advantages and suitable applications.

ding wheel dressing, each with its advantages and suitable applications.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

- Diamond pen dressing This method uses a single-point diamond dresser or a diamond dressing blade for wheel dressing. After dressing with a diamond pen, the wheel may produce burn marks or wrinkles during grinding due to its wider cutting edge and less sharpness. Thus, it is necessary to appropriately sharpen with a diamond after dressing. This common method requires the diamond to contact the wheel below its axis and move at a uniform, slow feed rate.

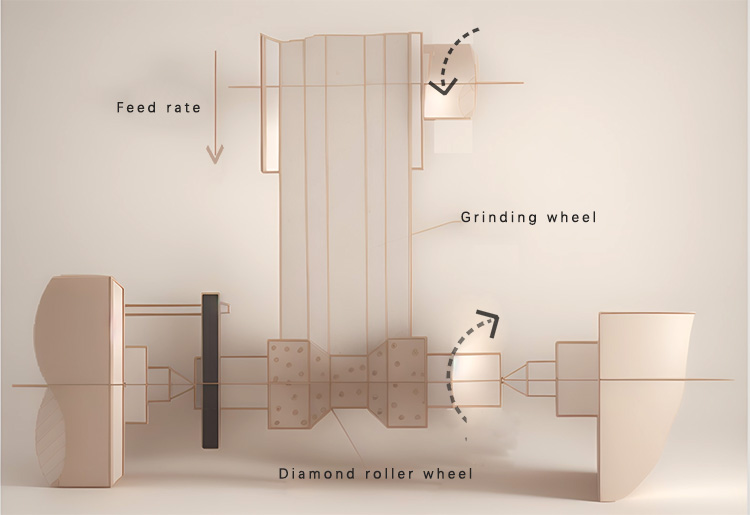

- Roller dressing This method involves using the relative rolling motion between the roller and the wheel to fracture the bonding bridges of the wheel, creating micro-edges on the abrasive grains. It is characterized by high dressing pressure and lower efficiency and precision but can produce sharper grains, suitable for certain specific applications.

- Grinding wheel dressing Ordinary abrasive wheels or diamond rollers are used to dress CBN wheels through grinding. This method allows dressing across the full width of the wheel simultaneously, with short dressing time, low dressing force, and the ability to replicate complex wheel profiles.

II. The importance and methods of wheel dressing

- Purpose and importance of dressing Dressing is not only about restoring the original grinding performance and geometry of the wheel but also involves a sharpening process. This creates sharp cutting edges and clears fine materials from the wheel’s surface pores to prevent an increase in grinding force and burning of the workpiece surface.

- Preparation before dressing Before dressing, it is important to maintain a certain temperature in the main spindle bearings to prevent geometric damage to the part and abnormal wear of the wheel and dressing tools. Additionally, as diamond dressing tools are very fragile, they must be handled carefully.

- Use and maintenance of dressing tools Using a blunted dressing tool will degrade the grinding performance of the wheel. Therefore, it is necessary to maintain the sharpness of the diamond dressing tool, rotating its tip regularly to keep it sharp.

- Selection of dressing methods Depending on the application and type of grinding wheel, different dressing methods like diamond pen, diamond roller, grinding, and roller dressing can be chosen. Each method has its specific application scenarios and advantages.

Here, I would like to invite readers to share your experiences. Do you have experience with Superabrasive grinding wheels? Which dressing technique do you usually use? Feel free to leave your insights and suggestions in the comments below.