Micro-milling processing: pros, cons, and apps

Micro-cutting processing Introduction. Micro-cutting processing belongs to the category of traditional machining, and its mechanism is similar to conventional cutting processing, which involves removing material from the workpiece surface using […]

Micro-cutting processing Introduction.

Micro-cutting processing belongs to the category of traditional machining, and its mechanism is similar to conventional cutting processing, which involves removing material from the workpiece surface using a cutting tool. The difference lies in the size range of components in micro-cutting processing, which is generally between 0.1 and 10mm, and the dimensional range of processed features is between 0.01 and 1mm, belonging to the mesoscale range. Micro-cutting processing includes micro-turning, micro-milling, micro-drilling, and micro-grinding. Among them, micro-milling uses milling cutters with a diameter below 1mm, or even smaller. Milling is one of the most flexible cutting methods, and micro-milling enables the diverse processing of small, three-dimensional complex-shaped components.

Advantages and limitations of micro-milling technology.

Compared to other micro-cutting methods, micro-milling technology has the following advantages:

- Processing of various materials: Micro-milling can process various materials by removing material from the surface of the workpiece using a cutting tool. In theory, by choosing appropriate hardness and strength of the tool, it is possible to process different materials.

- Strong three-dimensional processing capability: It can achieve fast, reliable, and repeatable processing of freeform surfaces and complex three-dimensional features at the mesoscale.

- High processing accuracy: By using PCD (polycrystalline diamond) and single crystal diamond micro-milling cutters, it is possible to stably achieve machining accuracy and surface roughness better than 100nm in micro-milling.

- Low processing cost: The processing cost of micro-milling is relatively low compared to other micro-processing methods such as photolithography, micro-electrical discharge machining, and micro-electrochemical machining. Additionally, the ability to produce components in large quantities with repeatability contributes to the low processing cost.

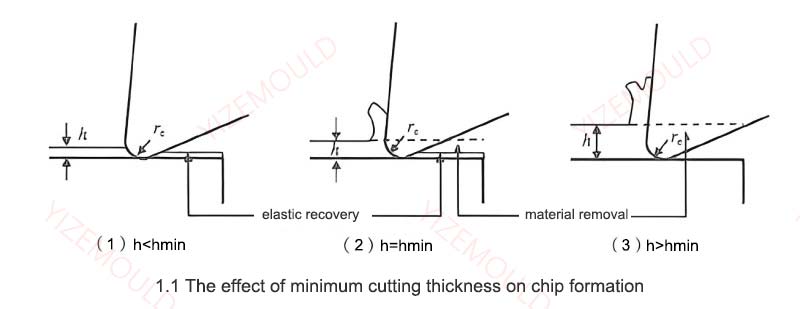

Although micro-milling has many advantages compared to other micro-cutting methods, it also has its limitations. Micro-milling is not simply a reduction in size of macro milling compared to conventional macro milling. In the micro-milling process, when the cutting parameters decrease to the same order of magnitude as the cutting edge radius or the grain size of the workpiece material, it exhibits different cutting characteristics from macro-milling, such as size effects and minimum chip thickness phenomenon. The size effects and minimum chip thickness can lead to different cutting mechanisms and varying degrees of tool wear and machining defects, which can limit the application of micro-milling technology in production. Furthermore, the manufacturing of micro-milling cutters and the maintenance of sharp cutting edges also affect the process and surface integrity of micro-machining. Therefore, extensive theoretical and experimental research is still needed to address the existing deficiencies in micro-milling processing technology.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Applications of micro-milling technology.

Traditional micro-milling technology mainly uses micro-end mills with diameters ranging from tens of micrometers to one millimeter for micro-machining on conventional-sized ultra-precision machine tools. Since these machine tools are primarily used for high-precision machining of non-microscale geometric parts, complex designs and processes are required to achieve the desired accuracy. However, they lack the necessary flexibility for machining small components and have high costs and low efficiency. Miniaturized machining equipment has the advantages of high flexibility, high efficiency, high integration, and low cost.

With the development of technology, the demand for small components in society continues to increase and quietly changes people’s lifestyles. For example, smartphones are evolving towards miniaturization, lightweight, and intelligence, requiring the use of various micro-machining technologies to manufacture micro-structural components. Micro-milling technology, as a low-cost and rapid processing method for small components, has been widely applied in fields such as aviation, communication, automotive, and optics.